SPECIALS

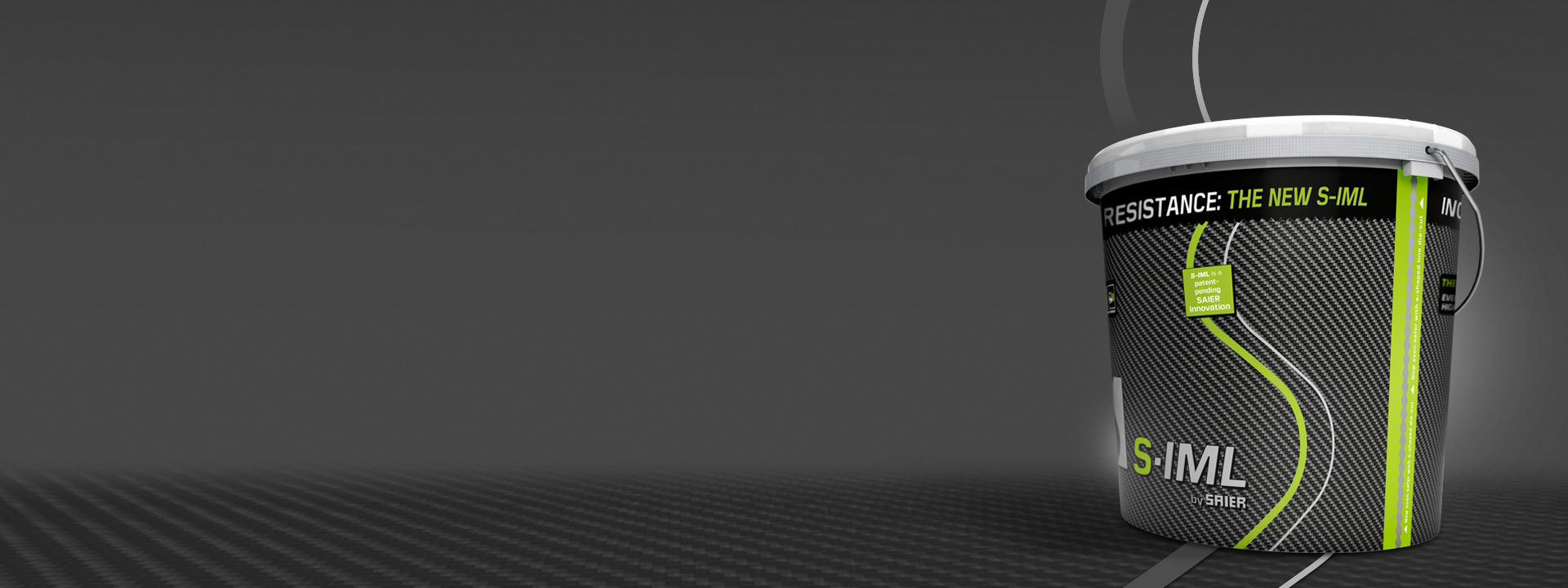

S-IML: IML decorated containers achieve new safety level!

Throughout its life cycle, SAIER packaging is regularly subjected to considerable strains, including filling and transport processes, during use in shakers, or as the result of rough treatment by the user.

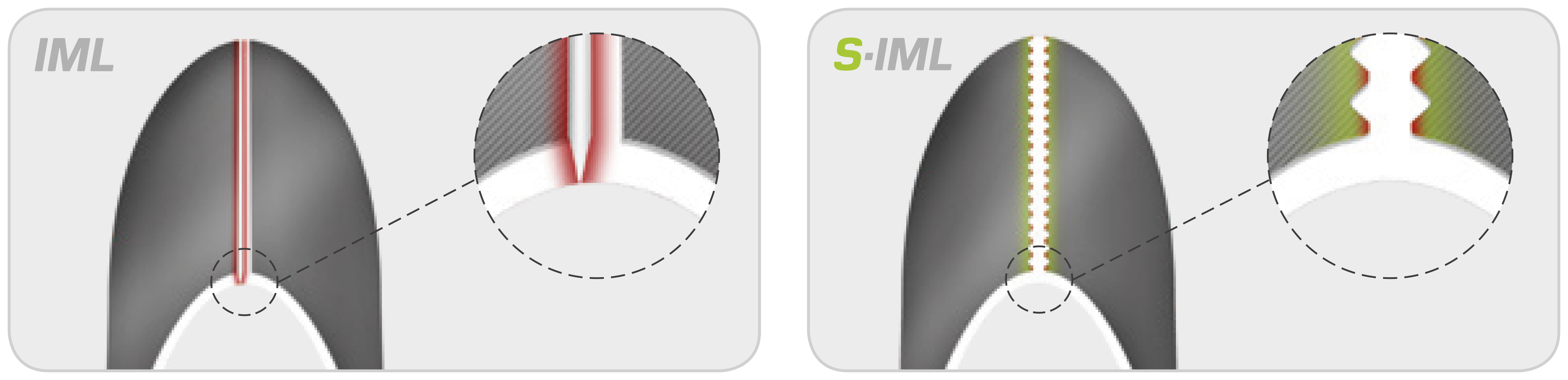

Rough treatment of the packaging of IML decorated containers* can result in breakages between the joint of IML and the container matrix material. This is caused by the extending linear stress concentration at the joints under high stresses.

In an effort to further increase these resistance values for SAIER packaging, we have developed our S-IMLs. S-IMLs are characterised in particular by the fact that they continually adapt the design of the joint to the container matrix material, and so effectively prevent stress concentrations from occurring under pressure loads. S-IMLs are available as a partial and all-round label.

The impact of this on the development, for which we have applied for a patent, ensures that our packaging achieves a completely new level of safety. If this increased safety means that our packaging better meets your safety requirements, we would be delighted to talk to you about using our S-IMLs in your packaging.

* IML stands for In-Mould Label. The IML process involves a plastic film decorated in planographic printing being placed in an injection mould, and back-injected with a thermoplastic matrix material. The film thus conjoins to the matrix material.

How S-IMLs work